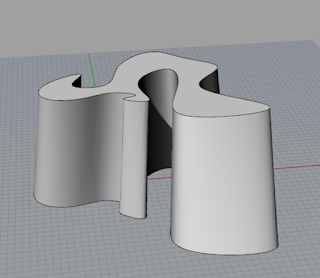

This is my concept that was chosen out of my 10. It has essentially no function and was made purely for aesthetics.

I know that my sketches are incredibly crude but I've always found that quickly getting mt ideas onto paper is much more effective for me than putting time into properly drawing the concepts in a realistic manner. As well I find doing really rough concepts helpful because the less refined they are, the more there is open to interpretation. This leaves room for new ideas to be easily added in your mind if any come up in the future.

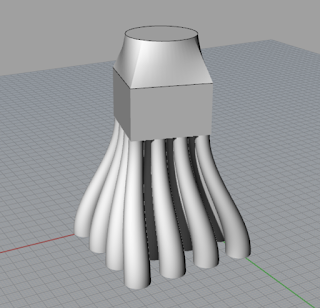

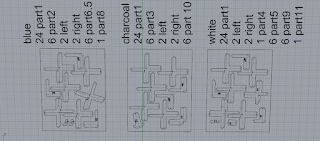

Mark and I were pretty stumped on the combination of our 2 designs for quite some time. A lot of the ideas we were making into rhino models were definitely visually interesting but there was just something missing from all of them. We remained stumped with one of our concepts until we realized that we could essentially just take the cap off of it and turn it into a chalice. With a few hours of mixing and refinement we ended up with something that I think we are both pretty proud of. For assurance we each made our own final version of the chalice idea so we could have 2 options of models to print.

For an unknown reason when we went to print off the chalice, slicer decided to make the center mesh handle solid. Because we were so caught up in the excitement of actually printing something off for the first time, neither of us realized that the one part was going to print solid until we were already 40 minutes into the print. So our options now are to either fix the model we are currently using or to send the 2nd model we created to the printer. Either of these two options would work fine.

Another modification I'd like to make to the model would be to decrease the angle at the base of the chalice. In our first attempt at printing some parts at the bottom got a little bit wispy because it was printing at such a high angle